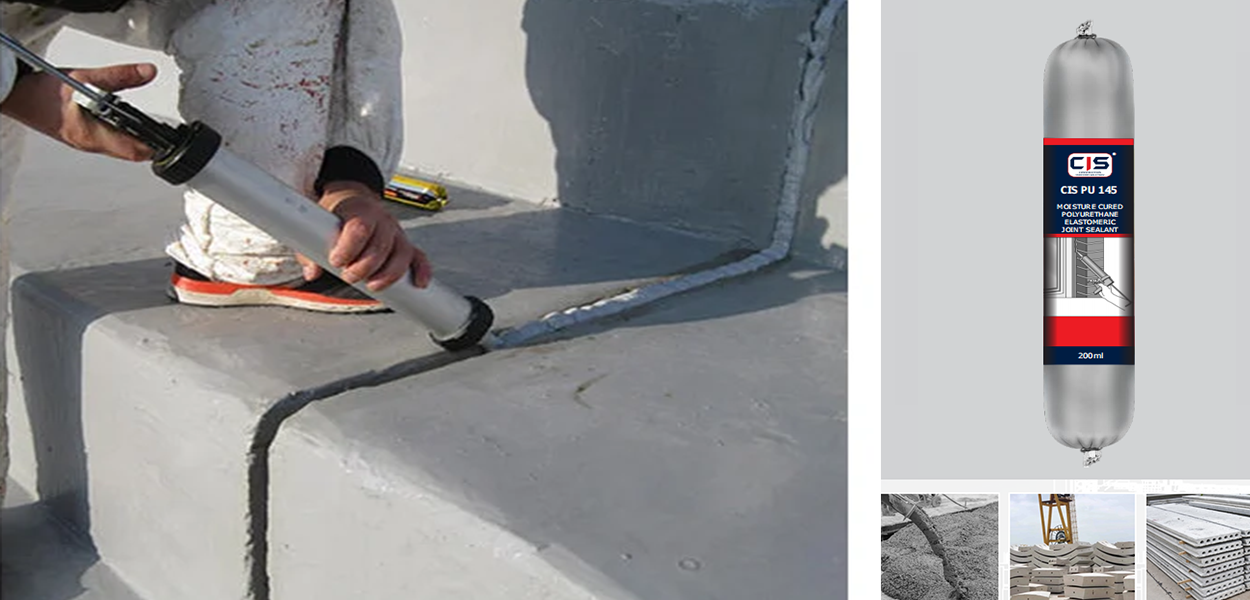

MOISTURE CURED POLYURETHANE ELASTOMERIC JOINT SEALANT

PRODUCT CATEGORY: : POLYURETHENE

SELENT

CIS PU 145 is a single component, Moisture cured Polyurethane elastomeric sealant, which resists crack arising out of movements of joint materials. It conforms to EN 14187-S 2003, BS 5212, ASTM C-920, ISO-11600

SURFACE PREPARATION

Remove all loose gravel, dirt, oil, grease and foreign matter by jet of dry air and clean

the surface

mechanically or by grinding to make it smooth before application.

Concrete surface must be dry and stable at least for 28 days.

Ensure that the moisture content in the prepared surface does not exceed 5% immediately

before

application of ShaliSeal® PU

To avoid adhesion of spill-over material beside joint, use masking tape at floor level

beside both sides to get

sharp edged neat and clean joint.

Use back up material to avoid third face adhesion and to avoid contact between joint

forming board &

sealant.

Use primer on vertical side faces of the joint to ensure strong bonding between

substrate and sealant

APPLICATION OF MATERIAL

Use Extruded polyethylene rod of diameter of 25% more of the width at the base as

separation layer,

construction & control joints as back up material to avoid 3-face adhesion and to avoid

contact between joint

forming board & sealant.

Prime the surface with CIS PU 145 @ 7 m2 / L in case of concrete surface and 10 m2 / L

in case of metal

surface.

After primer is surface dry and noticeable surface tack is generated, apply CIS PU 145

from the gun slowly

and fill. Smooth out with soapy water by pressing the mastic against the edges and the

joint.

Remove protection strip. Cleaning & Maintenance Clean the equipment with solvent like

Xylene, Toluene.

Scrap off cured sealant on the equipment. Health & Safety

Avoid contact with skin / eyes and avoid swallowing.

Ensure adequate ventilation and avoid inhalation of vapour.

Wear suitable protective clothing, gloves and eye protection.

In case of skin contact, rinse with plenty of clean water, then cleanse with soap and

water. Do not use solvent

to clean the contacted area.

In case of eye contact, wash with plenty of clean water and seek medical advice.

br If swallowed, seek medical attention immediately. Do not induce vomiting. Packing

Available in 600 ml

sausage. Storage Keep in cool dry place, under the shed, away from heat and humidity. Store

in proper

ventilated room and temperature should be between 10 - 25°C. Shelf Life 12 months in

original unopened

sealed condition

200 ml Sausage